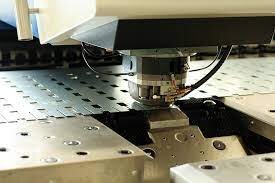

CNC Turret Punch

Overview

A CNC turret punch press machine pushes a piece of metal around to easily create numerous holes in a variety of different diameters. A typical punch may have up to 60 tools: holes of varying sizes, straight edges, commonly-used notches or mounting holes. These tools are all located in a turret that can be rotated to the punching position. A punch is less flexible than a laser for cutting compound shapes, but faster for repetitive shapes.

Turntable, also known as rotary head or turret, is used to store tools

Grille of an air-conditioning unit

Background

CNC stands for Computerized Numerical Control

These machines use pre-programmed computer software to dictate its movement and usually acts by removing material

Software

A Computer-aided Manufacturing (CAM) process first converts the Computer-aided Design (CAD). Softwares such as Radan may be used or you may manually type in CNC codes. The turret punch will require a clean DXF file.

Specifications of Amada

Maximum Sheet Size: 240” x 60”

Maximum Sheet Thickness: 0.177” mild steel

Maximum Material Weight: 110 lbs to 330 lbs

Local CNC Turret Press Providers

Weldflow Metal Products - 36th Floor, 1250, Broadway

Reference

https://en.wikipedia.org/wiki/Turret_punch

https://www.machinemfg.com/cnc-turret-punch-press-ultimate-guide